Injuries and fatalities in the workplace are a serious concern for government, organizations and the family members of those who work in safety-sensitive industries. In 2016, nearly 5,200 fatal workplace injuries were reported in the United States and in Canada, over 900.

Unfortunately, the statistics of serious workplace accidents are not experiencing the decline that regulatory bodies such as the Occupational Safety & Health Administration (OSHA) would like to see. As a result, many industries are facing increasingly strict regulations, and businesses are now legally obligated to train employees, implement safety programs and prove their diligence and compliance. Fortunately, the most common construction workplace accidents, which are referred to as the ‘fatal four’ by OSHA, are all occurrences that are preventable with the proper training and precautions. In this article, we walk you through the 'fatal four' and how your company can take proactive measures to reduce hazards.

Unfortunately, the statistics of serious workplace accidents are not experiencing the decline that regulatory bodies such as the Occupational Safety & Health Administration (OSHA) would like to see. As a result, many industries are facing increasingly strict regulations, and businesses are now legally obligated to train employees, implement safety programs and prove their diligence and compliance. Fortunately, the most common construction workplace accidents, which are referred to as the ‘fatal four’ by OSHA, are all occurrences that are preventable with the proper training and precautions. In this article, we walk you through the 'fatal four' and how your company can take proactive measures to reduce hazards.

Slips, trips and falls

Slips, trips and falls are the leading cause of workplace injury and fatality. In June, an Ontario roofing company was fined $100,000 after a worker fell to his death during a job. The company failed to ensure that either a guardrail system or a protective covering was used during the job to protect the worker from falling through an opening on the roof. Unfortunately, these cases are all too common but are almost always preventable.To mitigate the risk of a slip, trip or fall, organizations can adopt: good housekeeping to ensure worksites are dry, clean and free of debris; modified flooring to ensure slippery areas have abrasive coatings applied to increase grip; and requirements for employees to wear industry approved footwear. Most importantly, worksites that involve roofing, scaffolding, construction and other height-related risks should always adhere to industry protocol for harnessing, guard rails and other preventive equipment. For more advice on this workplace hazard, visit this information sheet from Workplace Safety and Prevention Services.

Struck by an object

OSHA estimates that roughly 10 per cent of occupational fatalities occur because of ‘struck-by’ accidents. This type of accident can be broken down into four categories:The use of proper personal protective equipment (PPE) such as face shields, reflective vests and hardhats can mitigate the risks associate with many struck-by accidents. Training employees on struck-by hazards can help to increase their awareness so that they avoid working beneath moving objects, inspect rigging before moving suspended loads, practice good housekeeping and securely store materials. For more information on avoiding struck-by hazards, view this OSHA presentation.

Electrocution

Overhead power lines, exposed live wires and contact with electrical currents from power tools or machinery are the most common types of electrocution accidents that occur in the workplace. The severity of an electrocution accident makes it the third leading cause of workplace injuries and fatalities on construction sites. When electrocuted, workers can fall, experience severe burns internally and in the worst cases, can suffer brain injuries that often lead to death.Safety training is the single best way to prevent electrocution in the workplace. Using insulation, grounding, guarding and electrical protective devices are effective preventive measures, but training supervisors and staff to recognize hazards and mitigate the risks is critical. Train employees to:

Shut off electrical currents before inspecting or repairing materials

Properly maintain electrical equipment and tools

Use appropriate protective equipment and circuit protection devices

Exercise caution when working near live wires or power lines

Safety standards for electricity should be worked into your organization’s health and safety policy, and training should be re-administered on a regular basis. Follow OSHA’s guidelines for electrical safety to keep your wires and workers safe.

Safety standards for electricity should be worked into your organization’s health and safety policy, and training should be re-administered on a regular basis. Follow OSHA’s guidelines for electrical safety to keep your wires and workers safe.

Caught in/between

Caught-in hazards occur when there is an opportunity for a worker to be caught in between objects. Often, these accidents occur around heavy equipment vehicles, when guards are disabled on power tools and when limbs or loose clothing/jewelry are caught in moving parts.To prevent caught-in and between hazards, employees should:

Each worksite and piece of machinery should be analyzed for potential caught-in hazards. The best way to keep employees safe and to prevent any workplace accident is awareness, training and diligence from leadership.

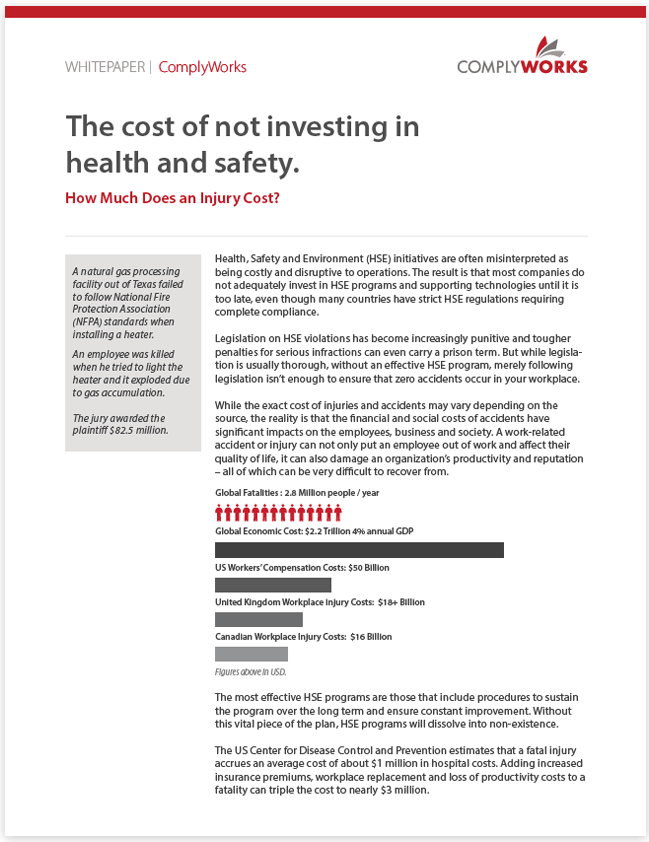

Health and safety initiatives are often misinterpreted as being costly and disruptive to operations. The result is that most companies do not adequately invest in safety programs and supporting technologies until it is too late. While the exact cost of injuries and accidents may vary depending on the source, the reality is that the financial and social costs of accidents have significant impacts on the employees, business and society. A work-related accident or injury can not only put an employee out of work and affect their quality of life, it can also damage an organization’s productivity and reputation – all of which can be very difficult to recover from. To read more on the cost of health and safety, download our white paper below.