At the core of the supply chain practice is risk management. Organizations must ensure that their operations and third-party contractors who control the production and flow of goods – all the way from raw materials right down to consumer delivery – are compliant with legal regulations, are ethically sound and are fiscally responsible.

Famous Italian clothing brands including Louis Vuitton, MaxMara and Fendi are currently facing scrutiny for working with manufacturers that are paying outsourced workers unfair wages under the table to cut costs – an unethical practice that will surely have reputational consequences on the major clothiers.

But aside from reputational damage, third parties also introduce operational and legal risks. In April, an Ontario construction company was fined $90,000 after a worker fell from a ladder and suffered critical injuries. The construction company hired a contractor to perform electrical work and although the injured was employed by the contracted company, the employing company was fined for negligence.

Famous Italian clothing brands including Louis Vuitton, MaxMara and Fendi are currently facing scrutiny for working with manufacturers that are paying outsourced workers unfair wages under the table to cut costs – an unethical practice that will surely have reputational consequences on the major clothiers.

But aside from reputational damage, third parties also introduce operational and legal risks. In April, an Ontario construction company was fined $90,000 after a worker fell from a ladder and suffered critical injuries. The construction company hired a contractor to perform electrical work and although the injured was employed by the contracted company, the employing company was fined for negligence.

In the complex supply chain environment where many moving components are outsourced, it is critical for businesses to ensure they hire third-party contractors that are compliant with health, safety, environmental and ethical standards. This can be particularly challenging for businesses with international supply chains, that work with hazardous materials and that are in safety sensitive industries. The companies that proactively identify risks and plan for contingencies are those that are better prepared to maneuver disruptions when third-party risk manifests. A successful third-party risk management program should take these three steps:

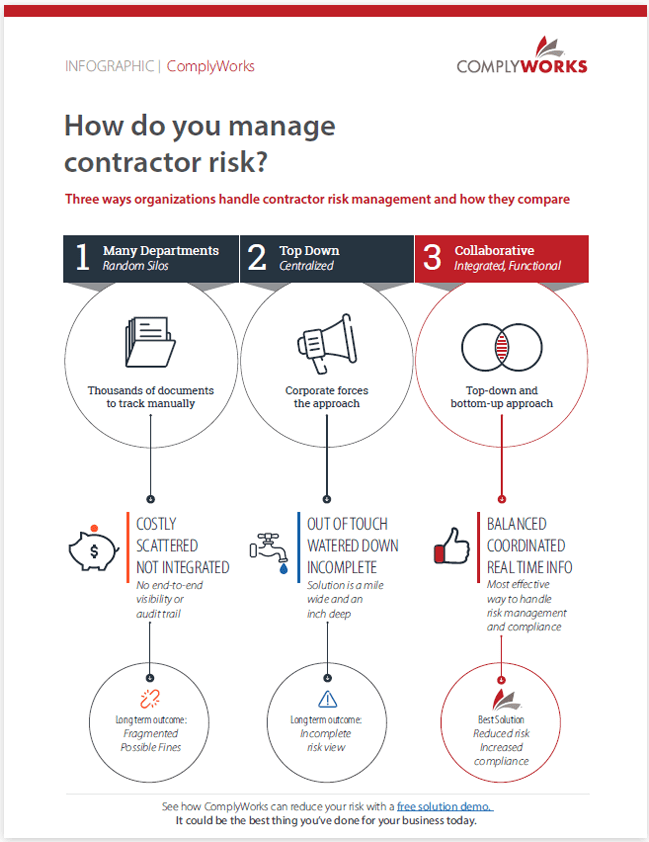

1) Creating a risk-aware culture and control team

If dispersed across an organization, risk management can quickly become siloed, disjointed and ineffective. A risk-aware culture should begin with senior leadership and flow down throughout the entire organization. While risk management should be controlled from a central function, assigning champions from each department for cross-functional awareness and buy-in is the first step to risk alignment across a large organization. Use past experiences to establish realistic goals and objectives while also forecasting for the future and taking into consideration the direction of the company.2) Evaluating the risks

What is your organizations risk profile? If you are a high-end clothier and fashion brand, your risk profile may be entirely different than that of a commercial construction company, as seen in the above example. By defining your risk profile, you can begin to determine the third-party risks that you may need to pay closer attention to, including:Examine each area of your supply chain, from raw materials supply through to transportation, for hazards related to each of the above areas. Strategize as to how you can mitigate these risks and develop emergency response plans for when they do escalate.

3) Monitoring, auditing, reporting and improving

Many organizations are using outdated tactics like spreadsheets and paper documentation to track their third-party compliance. If this sounds like your business, it’s time to jump into the 21st century and digitize your compliance reporting. One, centralized system to automate contractor prequalification will help you to manage third-party risk throughout your entire supply chain. Choose a solution that allows you to:Thriving in today’s complex and globalized business environment comes down to a proactive outlook on risk management. Understand that your third-party contractors, suppliers and vendor’s risk is also your risk, and taking steps to accept and control that risk will improve the flow and efficiency of your entire supply chain.

To learn more about risk management in the supply chain, join us for a free webinar on Tuesday, October 30, 2018 from 11 am – 12 pm MDT.